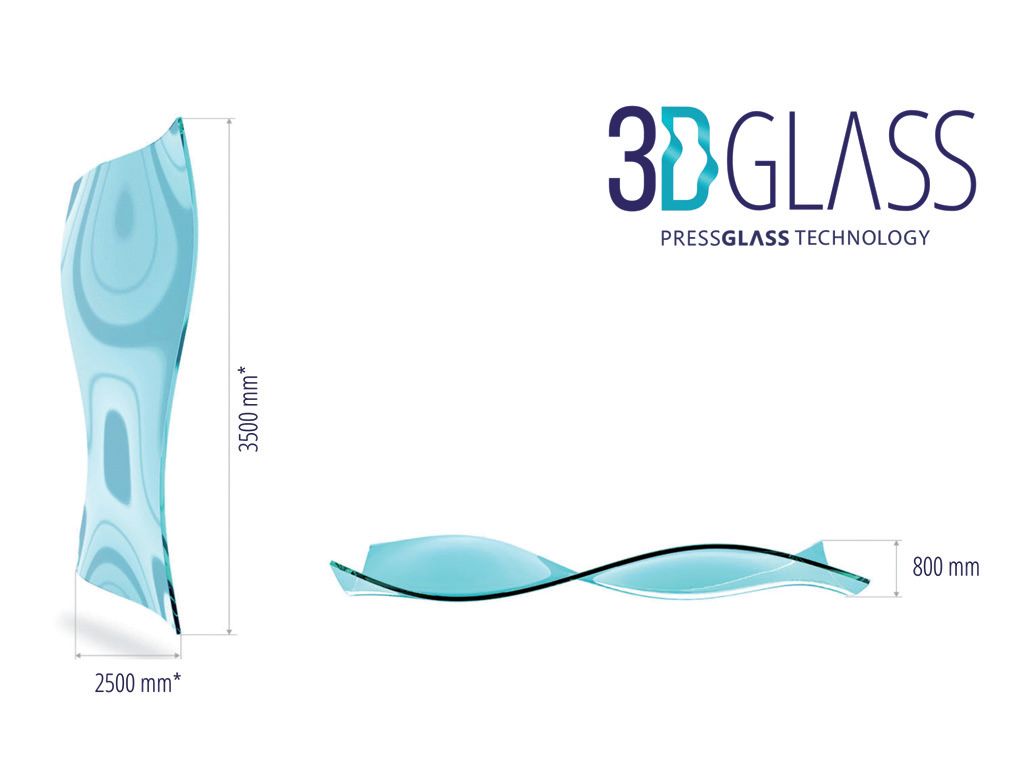

Thermally formed 3D GLASS is a revolutionary, patented by PRESS GLASS SA, technology bringing you vaster than ever possibilities to shape three-dimensional, uniquely shaped glass surfaces and facades built with geometrically varied elements.

3D GLASS from PRESS GLASS means a new approach to thermoforming of glass using a patented technology based on ceramic moulds instead of the previously employed metal moulds.

An efficient forming process of individual ceramic moulds gives more freedom in forming of large surfaces composed of unique glass panes.

Due to PRESS GLASS innovative technology, glass surfaces and building facades may now be constructed with uniquely shaped glass panes – easier and faster than ever before!

It is possible to use single or laminated glass panes with the newest high selective coatings and connecting them with spacer bars, to offer energy efficient double or triple glazed units.

Thus greatly improving indoor environment quality and sustainability of buildings, by reducing heat losses and limiting sun penetration.

3D GLASS – main advantages

3D GLASS is a product which fills the gap on the market of complex architectural forms using glass, built of geometrically different panes.

It is now possible to create 3D, seamlessly changing surfaces of glass facades when every single glass pane is approached and formed as a unique part of a larger construction – larger and seamlessly transforming glazing.

The possibility of using this kind of glass for the load-bearing construction of the façade, including point-fixing systems,

contributes to a better look of curvilinear glazing using 3D GLASS.

It all helps to maintain purity of the glass form within the curvilinear plane of the façade.

It should be emphasised that besides aesthetic appearance 3D GLASS contributes to achieving better sound-insulating properties and greater load resistance than flat glass.

3D GLASS can also be subjected to other processes which add to its functionality, e.g.:

- lamination – this way 3D GLASS becomes safety glass,

- printing with ceramic ink (screen print, digital print, enamel),

- double- and triple-glazed insulating glass units – this way thermal insulation characteristics of the

glass increase.

3D GLASS is already available in the PRESS GLASS offer. The maximum size of a glass pane is 2500 mmx 3500 mm.

Learn more: http://www.pressglass.com/3dglass/

Całość artykułu w wydaniu drukowanym i elektronicznym

Inne artykuły o podobnej tematyce patrz Serwisy Tematyczne

Więcej informacji: Świat Szkła 1/2019